In industrial operations, decisions are made every day based on measurement data. Flow, pressure, level, energy use; These are not abstract figures, but steering signals that directly impact safety, quality, and cost. A deviation of just a few percent in a flowmeter can result in product loss, environmental damage, or even downtime. And with audits becoming more detailed and regulations increasingly strict, inaccurate measurements are no longer just a technical issue, they are a compliance risk.

That is why we don’t see calibration as a side activity, but as a strategic tool. If you measure, you need to be sure you’re measuring right.

New rigs, new precision

Since moving into our larger facility in 2024, we have significantly expanded our calibration capacity. Our service workshop in Oud Gastel is equipped with modern rigs capable of calibrating a wider range of instruments, including both ultrasonic and electromagnetic flowmeters.

This expansion aligns seamlessly with our ISO 9001:2015 certification, ensuring our processes meet internationally recognized quality standards.

Five direct benefits of calibration

Calibration delivers tangible value—not as a theoretical obligation, but as a practical investment in:

- Process reliability – Deviations are detected and corrected in time.

- Quality assurance – Instruments remain within specification.

- Safety – Faulty signals and related risks are avoided.

- Cost control – Less waste, energy loss, and downtime.

- Compliance – Demonstrable reliability of measurement data under regulatory scrutiny.

On-site or In-house calibration

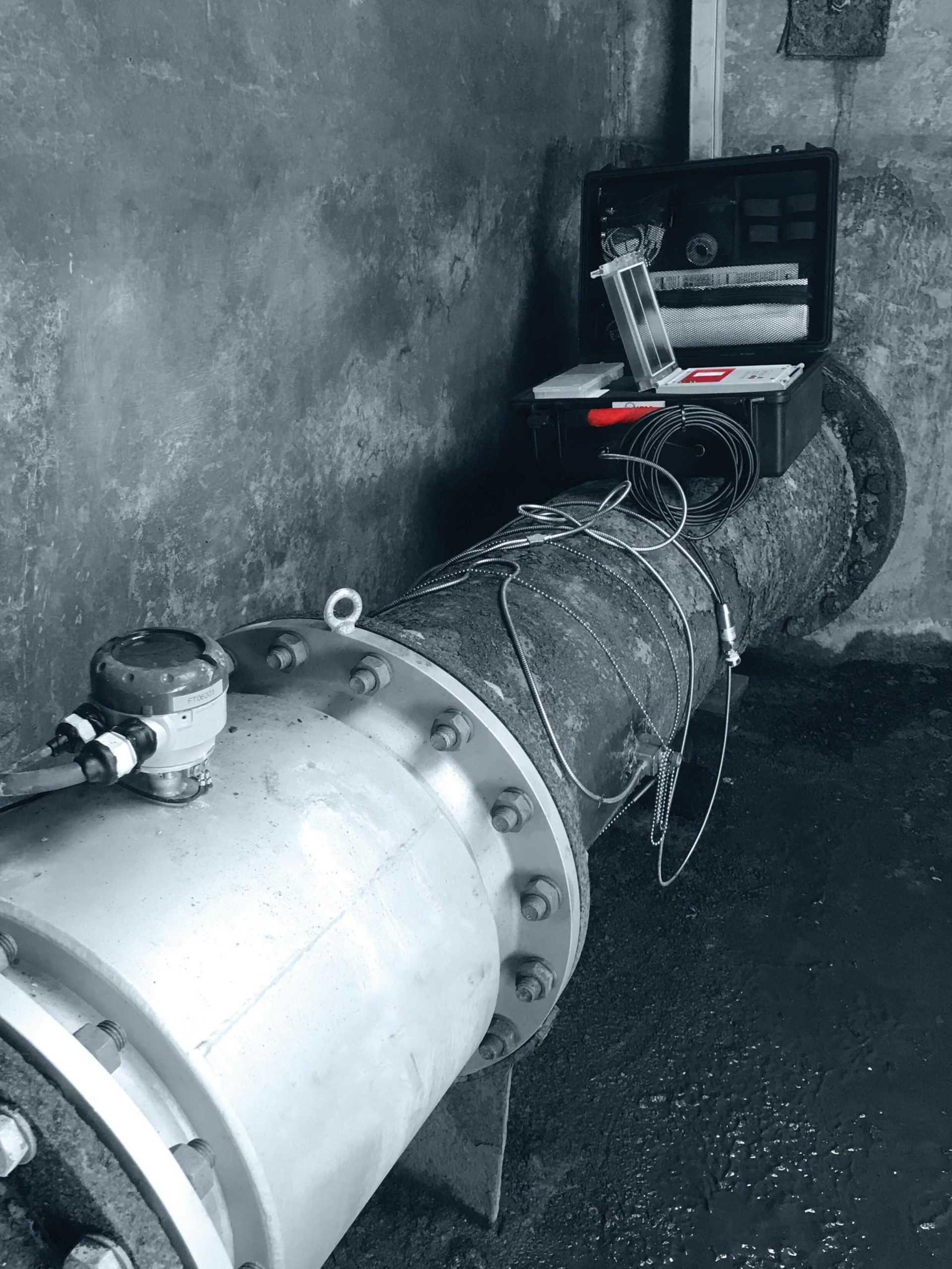

Depending on your requirements, we offer calibration in our fully equipped workshop or directly on site. In the latter case, our technicians use mobile rigs, meaning instruments don’t have to be dismantled for calibration.

We also provide tailored measurement solutions: for companies in need of temporary capacity or additional flexibility, rental or leasing is an efficient option. These services are particularly useful for peak demand, instrument replacement during maintenance, or short-term projects. For long-term applications, we of course also supply new instruments that fit seamlessly with your operational strategy.

How often is enough?

Calibration frequency depends on application, usage intensity, and process criticality. In many cases, annual calibration is sufficient. But for high-urgency processes, shorter intervals may be necessary. Based on historical data and industry experience, we help organizations define the right calibration policy.

Calibration as a foundation for the future

Reliable measurement data is the cornerstone of digitalization, sustainability, and process optimization. Smart systems only create value if the underlying measurements are accurate. That’s why calibration deserves a fixed place in any business strategy. Not as a cost center, but as a safeguard.

Measure to know. Calibrate to trust.

With a larger workshop, new rigs for ultrasonic and electromagnetic flowmeters, ISO certification, and flexible on-site support, we have taken our calibration services to the next level. Because at the end of the day, it’s not about numbers, it’s about trust: Trust that systems perform as intended, that audits run smoothly, and that processes continue to operate safely. Every day, calibration makes that possible.